As said before, the Traditional Balsamic Vinegar of Modena is produced by the fermentation of boiled grape-must, caused by particular types of "vinegar bacteria",

very often organized in a colony known as the "vinegar mother".

Besides this, the following slow maturity is due to the enzyme, which develops it after a long period of aging. During this period,

prevalently chemical-physical transformations take place.

The must used to produce the Traditional Balsamic Vinegar of Modena, is obtained from the pressing of Trebbiano grapes and other typical Modenese varieties, like Lambrusco grapes.

Before the uncooked must begins to ferment, it is separated from the skins of pressed grapes and then put in the vessels for cooking.

Here, the vessels are open and a slow concentration happens by evaporation.During the cooking process, a variable quantity of water evaporates and the

microbic charge present in the must at the beginning is devitalised to such a point that it loses its natural tendency to become wine. At the end of the cooking,

the must is golden brown, very savoury and sweet smelling, with a high sugar level.

The cooled and decanted cooked must is put in barrels of decreasing volume and of different woods (oak, chestnut-tree, mulberry, cherry tree, juniper, etc.).

The set of the barrels, each one made of a different wood is called a "battery".

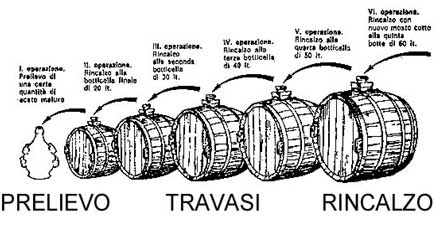

(Figure 1). It is placed under the roof of the houses where it is submitted to seasonal variations in temperature.

There are no fixed rules governing the number of barrels nor their capacity, nor even their sequence or wood types used. Every producer is free to organize his “acetaia” using barrels and woods types according to his taste and the quantity of product he wishes to obtain. Nevertheless, the minimum number of barrels is three: a big barrel to which the cooked must is added (where the acetic fermentation takes place), one middle-sized barrel to which the fermented liquid is moved to mature, and a third, the smallest, where the mature liquid is stored for the aging process.

Today the common tendency is to have a barrel battery of different woods and of decreasing capacity: the first, the biggest, contains the youngest product and the smallest that contains the mature one. Usually the sequence is made up of barrels which decrease in volume by 20-30 % at every step. For example, a series of five barrels may thus composed: 60-50-40-30 and 20 litres. If we start with a bigger first barrel of 75-litre capacity, we may obtain a series of eight barrels: 75-60-50-40-30-24-16 and 10 litres.

The general procedure regarding the wood types is to begin with tender and porous woods to let the evaporation ad acetification process take place (for example chestnut wood) and then go on to harder woods for the smaller barrels to aid the conservation of the mature product (for example oak or mulberry). The wood alternation contributes to a unique feature of the final product with a range of typical smells and aromas.

Into the acetifier barrel, the production of alcohol is obtained by the fermentation of the sugar of the boiled must brought about by a yeast (Zygosaccharomyces, normally present in the must) and the immediate acetification of the alcohol produced by the acetobacteria. Over time, the sugar, alcohol, aldehydes and organic acids of the boiled must undergo many profound transformation processes which produce the delicate and pleasant bouquet of the final product.

The production follows the course of season: the cold of winter gives limpidity to the traditional balsamic vinegar, while the heat of summer concentrates the sugar, alcohol and flavours, and the milder temperatures of spring and autumn allow for the microbiological activities. Every year, during cold season, a certain quantity of mature vinegar (normally about 25-30% of the contents) is taken from the smallest barrel. The smallest barrel will be refilled to two thirds of total capacity using the contents of the nearest (slightly larger) barrel (this procedure is called decanting, the “travaso”). This second barrel will be refilled with the third and so on until the last (the biggest) barrel of the battery. The biggest barrel will then be refilled with the year’s cooked must. This operation is called topping up, “rincalzo”.

In the biggest barrel, the cooked must begins its fermentation and acetification and the typical peculiarities of Balsamic vinegar are very young. In the smaller barrels the bacteria work more slowly, before ceasing and beginning the aging process. As described above, in winter we withdraw the right quantity of mature balsamic vinegar from the smallest barrel of the battery. If we have a set of seven barrels with the smallest of ten litres, which is refilled at ¾, it contains 7.5 litres of vinegar of which we may take 2.5 - 3 litres at most so as not to alter the production of the vinegar with the excessive refilling from the next barrel along.

The Traditional Balsamic Vinegar of Modena is a Controlled Denomination of Origin Product (DOC) and it also has a Denomination of Protected Origin (DOP). the product is sold as an ABTM aged 12 years and an ABTM “Extra Vecchio” aged 25 years.

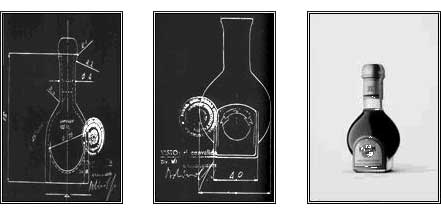

The product is protected by the ABTM Producers’ Consortium, “Consorzio tra Produttori di ABTM” and only after the ABTM has passed a set of organolepctic controls, may a 100cc bottle be filled which is unique to all the producers (Figure 2). Every bottle is numbered and corked with the seal of warranty, and for every lot of ABTM the Producers’ Consortium keeps a small amount of the ABTM in order to warrant the quality of the ABTM bottled.

Figure 2:Exclusive bottle created by Giugiaro Design for commercialisation of ABTM. The bottle, of transparent glass, contains 100 cc of vinegar and shows the numbered plate of Producers’ Consortium and the warranty seal.

The ABTM is a one-of-a-kind product of highest quality and closely tied to its region of production. Its possible market is restricted by its high quality and equally high price. The target buyers are exclusively lovers of fine foods, gastronomic boutiques, restaurants and stocks of high quality vintage wines. It is marketable all over the world and when ABTM is bottled in glass there are no problems with its conservation or deterioration.